Multi-functional Cold Foil and Cast&Cure Machine

Multi-functional Cold Foil and Cast&Cure Machine

Introduction

The machine can be connected with the automatic screen printing machine to be the new production line integrating wrinkle, snowflake, spot UV , cold foiling as well as the cast & cure process. The combination of five processes can efficiently use the equipment and reduce the purchase cost.

Especially when no other special process is required for printing, the spot UV curing can be used efficiently alone.

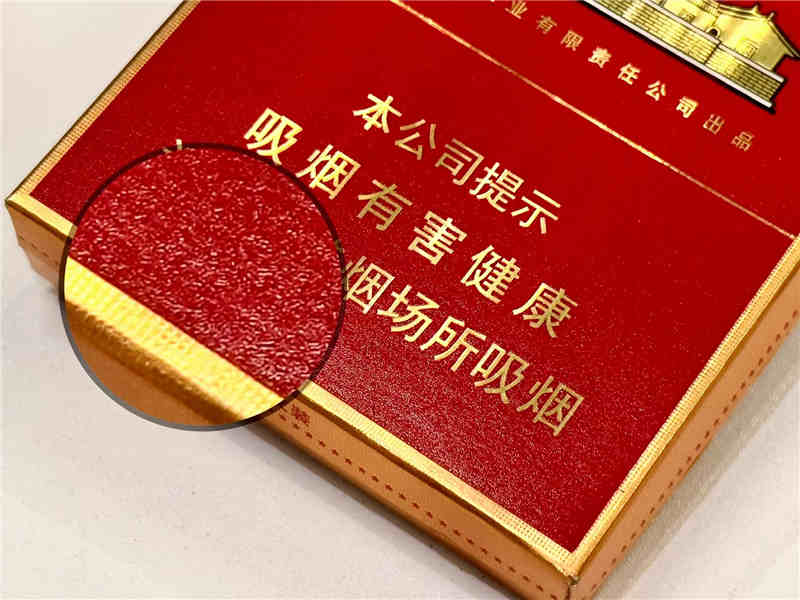

(Cold Foil Effect)

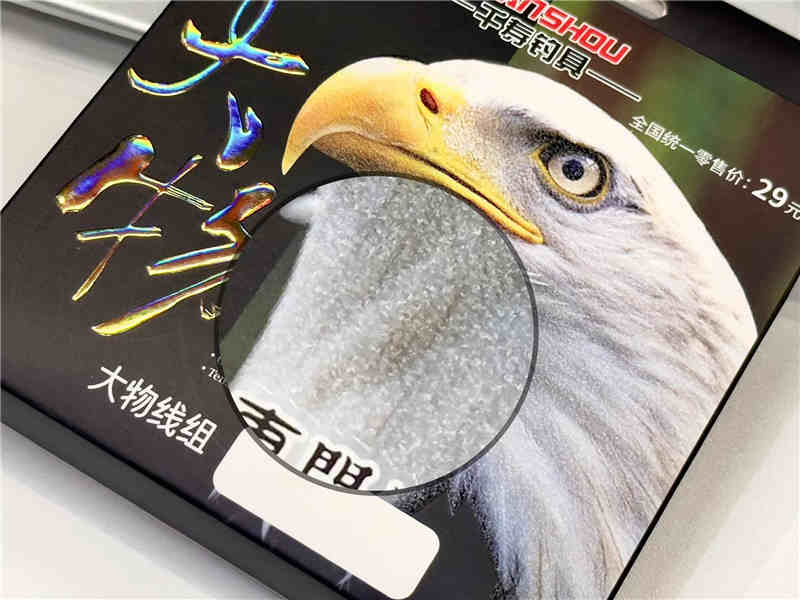

(Snowflake Effect)

(Wrinkle Effect)

(Spot UV Effect)

(Cast&Cure Effect)

Technical specification

| Model | LT-106-3Y | LT-130-3Y | LT-1450-3Y |

| Max sheet size | 1100X780mm | 1320X880mm | 1500x1050mm |

| Min sheet size | 540x380mm | 540x380mm | 540x380mm |

| Max print size | 1080x780mm | 1300x820mm | 1450x1050mm |

| Paper thickness |

90-450 g/㎡ cold foil:157-450 g/㎡ |

90-450 g/㎡ cold foil:157-450 g/㎡ |

90-450 g/㎡ cold foil:157-450 g/㎡ |

| Max diameter of film roll | 400mm | 400mm | 400mm |

| Max width of film roll | 1050mm | 1300mm | 1450mm |

| Max delivery speed |

500-4000sheet/h

Cold foil: 500-2500sheet/h |

500-3800sheet/h

Cold foil: 500-2500sheet/h |

500-3200sheet/h

Cold foil: 500-2000sheet/h |

| Total power of equipment | 55KW | 59KW | 61KW |

| Total weight of equipment | ≈5.5T | ≈6T | ≈6.5T |

| Equipment size (LWH) | 7267x2900x3100mm | 7980x3200x3100mm | 7980x3350x3100mm |

Main Advantages

A.Touch screen integrated control of the whole machine, with various fault prompts and alarms, which is convenient for operation and maintenance.

B.Cold foil system can be installed multiple different diameter rolls of gold film at the same time. It has the function of gaping gold when stamp the sheets. It can complete print jumping gold between sheets and within sheets. This system can help customers to save foil a lot.

C.The winding and unwinding system uses the film roll transposition device with our patented technology, so that the film roll can be easily and quickly transferred from the winding position to the unwinding position, greatly improving production efficiency, reducing manual operation intensity and improving safety performance.

D.The UV lamp adopts electronic power supply (stepless dimming control), which can flexibly set the energy intensity of the UV lamp according to the process requirements to save energy and power.

E.When the equipment is in the standby state, the UV lamp will automatically switch to the low power consumption state. When the paper is detected, the UV lamp will automatically switch back to the working state to save energy and power.

F.The equipment has a film cutting and pressing platform, which makes it easier to change gold film.

G.The pressure of the cold-foil roller is adjusted electronically. The stamping pressure can be adjusted accurately and controlled digitally.

H.The delivery machine is an independent machine, which is easy to detach, and can flexibly choose whether to install a 2m air conditioner at the front end to cool down later (2m cooling is more effective).(chiller is optional)